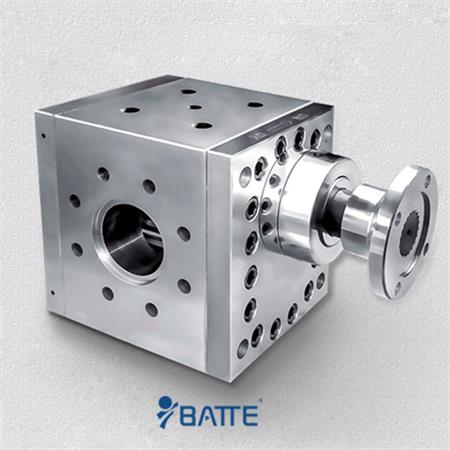

High Pressure Extrusion Melt Pump for Plastic Pipe Extrusion Line

Plastic extruder melt pump is installed in the extrusion line of a gear pump, pump accurate pressure measurement before, through the PLC to adjust the extruder speed, pressure stability, and orderly increase the flow to optimize the feeding process. Widely used in PC, PMMA, PET, ABS, PVB, PS, PP, PE and other high and low viscosity materials metering and pressurization.

Plastic Extruder Melt pump shell made of high quality alloy steel, gear with hardened chrome steel or other high quality metal materials, with high efficiency, leakproof, etc. Users can according to actual needs, take electric heating, sealed Select spiral labyrinth seal (dynamic seal), vacuum screw seal and special combination of seal configuration. Melt pump with straight teeth, helical teeth, and patented design of high precision, low pulse, low temperature rise, low shear herringbone teeth, for different transport medium, pump material selection, Witt can provide titanium alloy , Chromium-nickel alloy combination of materials. The gear pump is installed between the extrusion main unit and the machine head so that the fluctuations in the extrusion direction can be separated from the machine head and downstream equipment.

Regardless of the pressure at the inlet of the gear pump of the plastic extruder melt pump fluctuating, as long as the material entering the gear pump can fully fill the cogging, the gear pump can deliver material to the head at a steady pressure and flow rate, No fluctuation out of head, thereby enhancing the stability of the entire extrusion system and product accuracy. At the same time, as the plastic extruder melt pump gear pump is a supercharger, it can measure the metering section of the supercharger function transferred to the gear pump to complete, thus avoiding the extruder head work under high pressure When there is power consumption, shear stress, friction, materials stay a long time, easy to degrade and other shortcomings, so that extrusion productivity, extruder wear and tear reduced. In addition, the use of plastic extruder melt pump can also increase the controllability of the system, reduce the material temperature, reduce energy consumption and achieve linear output.

ZB-B Plastic Extrusion Pump Operating Parameter:

Theory: Positive Displacement Gear Pump

Structure: Gear Pump

Power: Electric or Oil

Fuel: No Need

Pressure: High Pressure

Volume Range: 0.5CC - 3200CC

Viscosity: ≤40000 Pas

Working Temperature: ≤400°C (750°F)

Cleaning Temperature: ≤450°C (850°F)

Outlet Pressure: 40MPa(6000psi)

Differential Pressure: ≤25Mpa

|

Type

|

CC/Rev

|

Capacity (L/H)

|

Heating power (kw)

|

Driven system (km)

|

|

ZB-0.2

|

0.2

|

0.1-0.6

|

0.5

|

0.37

|

|

ZB-1

|

1

|

0.5-3

|

1

|

0.5

|

|

ZB-2

|

2

|

1-6

|

1

|

0.75

|

|

ZB-5

|

5

|

2.5-15

|

1

|

1.1

|

|

ZB-10

|

10

|

5-30

|

1

|

1.5

|

|

ZB-20

|

20

|

10-60

|

2

|

2.2

|

|

ZB-31.5

|

31.5

|

15-90

|

2

|

3

|

|

ZB-50

|

50

|

25-150

|

3

|

4

|

|

ZB-100

|

100

|

50-300

|

4

|

5.5

|

|

ZB-150

|

150

|

75-450

|

5

|

7.5

|

|

ZB-200

|

200

|

100-600

|

6

|

11

|

|

ZB-250

|

250

|

125-750

|

8

|

15

|

|

ZB-315

|

315

|

150-900

|

8

|

18.5

|

|

ZB-500

|

500

|

250-1500

|

12

|

22

|

|

ZB-800

|

800

|

400-2400

|

15

|

30

|

|

ZB-1200

|

1200

|

600-3600

|

20

|

37

|

|

ZB-2500

|

2500

|

1300-7500

|

24

|

45

|

|

ZB-3200

|

3200

|

1600-9600

|

24

|

55

|

|

ZB-6200

|

6200

|

3000-18000

|

30

|

75

|