Quality standards for shaft seal maintenance of melt pumps

The shaft seal of the melt pump usually adopts packing seal, mechanical seal, or a combination of the two sealing methods; The maintenance standards for shaft seals should pay attention to the following four points:

1. The radial clearance between the packing gland and the shaft is 0.4~0.5mm, and the circumferential clearance is uniform.

2. The filler size is correct, the cut is parallel, neat, and free from looseness, and the interface is at a 30 ° angle to the axis.

3. When pressing the packing, the interfaces of each circle of packing must be staggered, with a general interface staggered by 120 °. The packing should not be pressed too tightly.

4. After the installation of the mechanical seal component, it passes the 0.2MPa pressure test for 30 minutes.

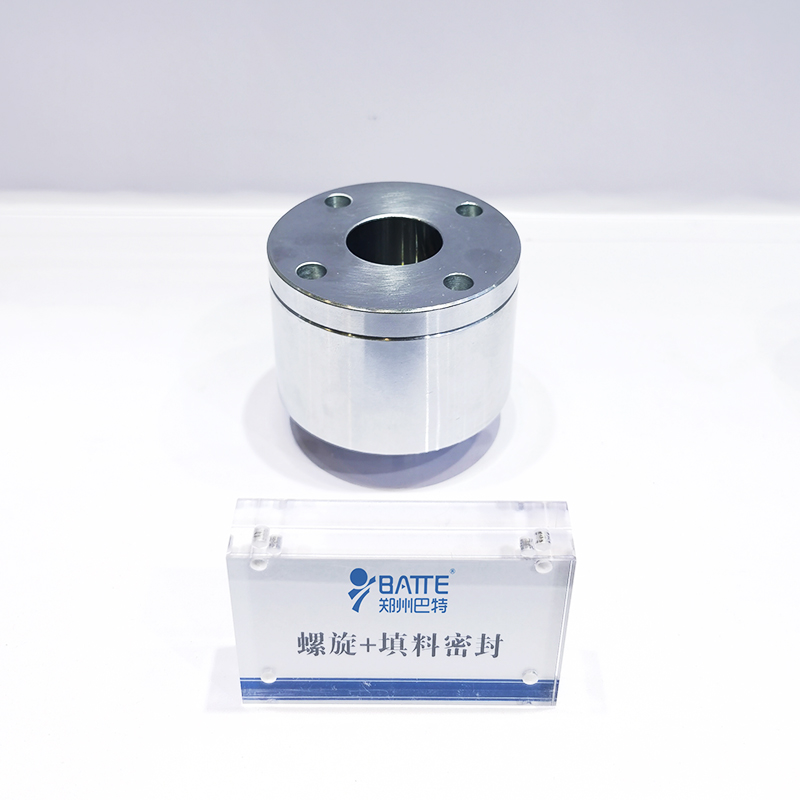

Melt pump screw+packing seal

The daily maintenance of the melt pump includes:

1. Regularly check the outlet pressure of the melt pump and do not allow overpressure operation.

2. Regularly check if the fastening bolts of the melt pump are loose and there is no noise inside the pump.

3. Regularly check the temperature of the stuffing box, bearings, and housing.

4. Regularly check for shaft seal leakage.

5. Regularly check the power supply.

Common sealing methods for melt pumps

Zhengzhou BATTE is a professional melt pump production and manufacturing enterprise, providing melt pump specifications and models ranging from 0.1CC to 20000CC. Welcome to visit and inspect the factory.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071