How to select the melt pump model?

Before helping the customer select a suitable high temperature melt pump model, it is necessary to understand and confirm the following working conditions with the customer.

First, what equipment is used together with? Generally speaking, the equipment used by customers include extruders, reaction kettles, equipment in chemical fiber industry, etc;

Second, we should be clear about the materials used by customers and their composition;

Third, the viscosity and temperature requirements of materials should be clear;

Fourth, understand the customer's requirements for pressure, such as high-pressure transmission or negative pressure transmission;

Fifth, understand the hourly output of customers.

The rubber and plastic extrusion production line adopts melt booster pump, and its advantages are mainly reflected in five aspects:

1. Stable output pressure;

2. Improve product quality;

3. Increase extrusion yield;

4. Reduce unit energy consumption;

5. Extend the service life of the whole machine.

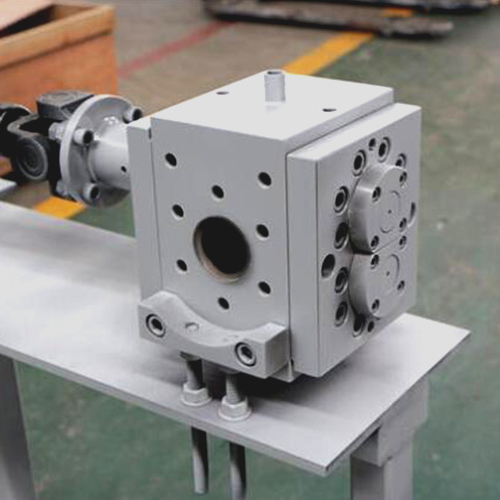

There are a variety of melt gear pumps suitable for resin, chemical fiber, rubber and other polymer material industries. At present, the extruder melt pump can meet all kinds of series products under all polymer working conditions. Including various heating methods: heat medium heating, electric heating, no heating; Various viscosity ranges: 0.1mPa. s to 4000000mPa. s; Wide temperature range: - 40 ℃ to 350 ℃; Wide pressure range: - 0.1 MPa to 35 MPa. At the same time, there are various specifications of melt gear pump: from 0.1cc/r to 12000cc/r. info@battemachinery.com