gaer pump assisted single-screw extrusion processes

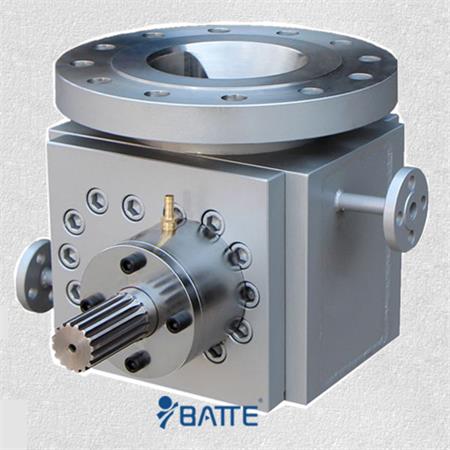

benefits of gear pump assisted extrusion, especially in single screw applications, is critically reviewed, and a method of predicting the operational conditions of.Gear pumps are often positioned between smooth-bore single-screw extruders and dies, providing several processing advantages. These advantages include the mitigation of pressure surges and thus flow surges from the extruder, a decrease in the discharge temperature by generating part of the pressure required for the die by the pump instead of by the extruder, reducing resin consumption, and for rate increases. For example, gaer pump assisted single-screw extrusion processes,if the extruder is operating with a relatively small pressure oscillation with time (or pressure surge) to the inlet of a gear pump, the gear pump will provide a nearly constant outlet pressure and flow rate to the downstream equipment such as a die.

Stable operations with a gear pump will allow plant personnel to operate at the lower specification limits for sheet or film and thus reduce the resin consumption per unit of product. If a gear pump is contributing to the generation of the discharge pressure for the downstream equipment, the metering section will operate with a higher specific rate as compared to a process without a pump. Extruders that operate at a higher specific rate will generally operate at a lower discharge temperature.